Handheld Bladder Scanner

The Verathon marketing team recognized the need for a low-cost, portable, handheld bladder scanner equipped with an on-board display. This new device targeted a previously unstudied user group. Our challenge was to develop a form factor for the scanner that seamlessly integrates with the user's workflow.

Verathon has successfully deployed its BladderScan i10 and other bladder scanners across the US, EMEA, and APAC markets. While these products are primarily designed for larger hospitals and urology clinics, they overlook a significant potential market: the home health sector. Traveling nurses, who serve this sector, have unique needs compared to their hospital-based counterparts. Therefore, it is essential to investigate a new form factor for the bladder scanner to meet these specific requirements.

Starting out

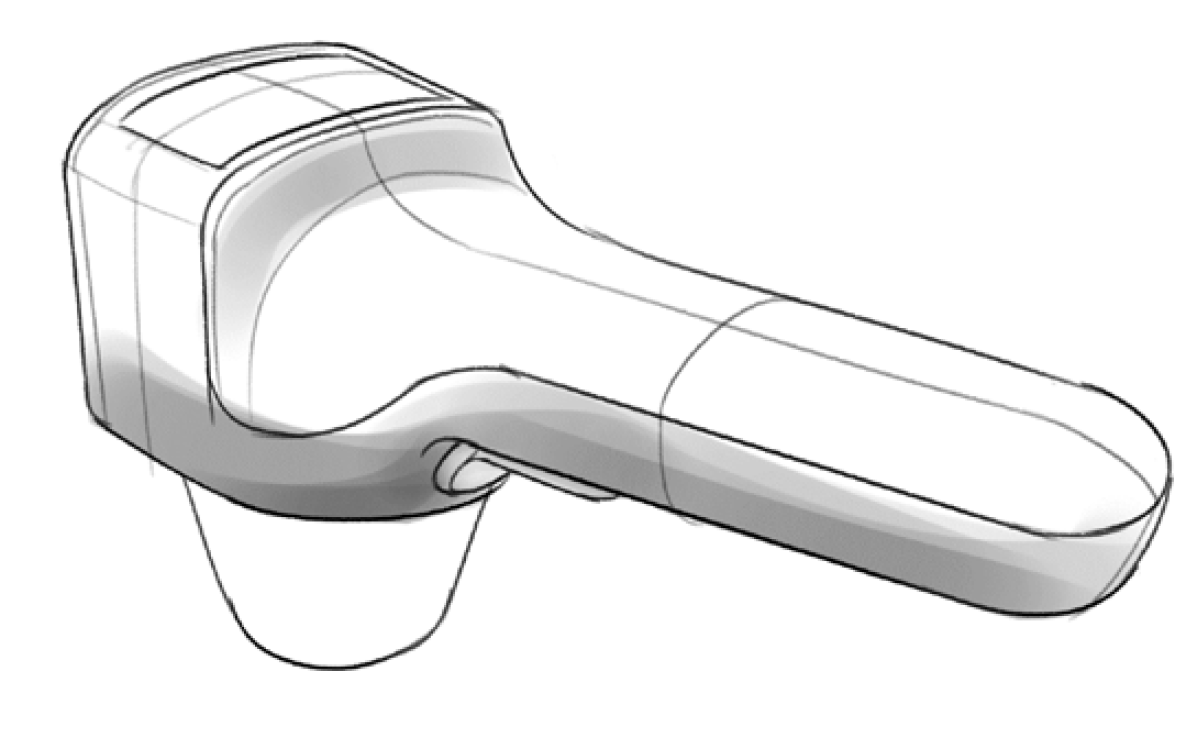

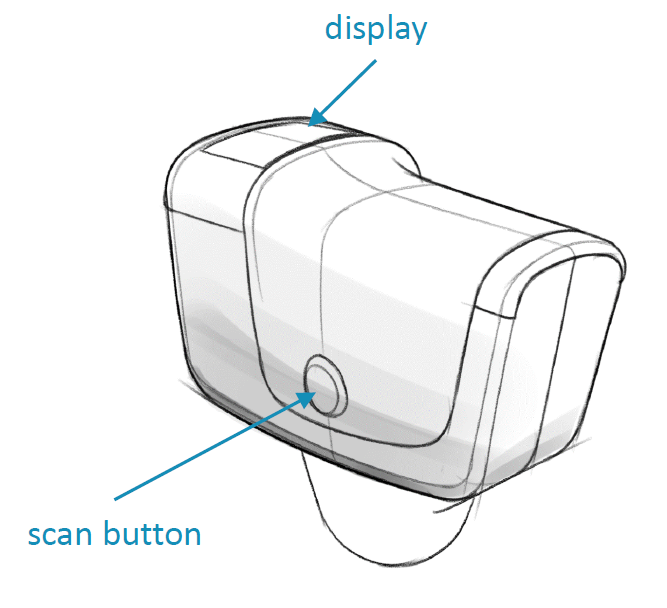

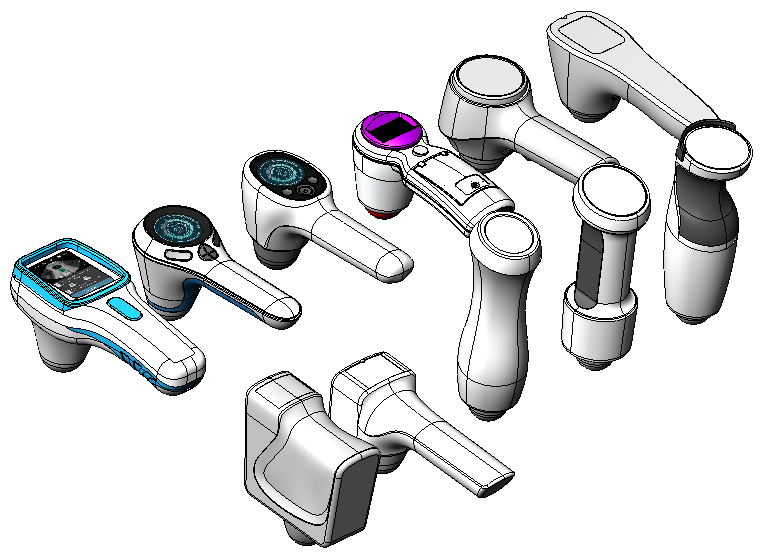

Our first task was to sketch various ideas and present physical prototypes to users. We hired an industrial designer for initial brainstorming, but they only provided rough 2D sketches. My colleague and I then translated these sketches into 3D models, which were subsequently 3D printed in an SLA printer.

Some concepts didn’t make the cut due to grip discomfort or confusing interfaces. Others succeeded in naturally fitting to the user’s hand, making them feel in control - these concepts were prioritized for refinement so that they could be presented to the team.

In total there were over 15 unique form factors that were generated - a significant portion were created by me after digesting and incorporating the feedback we were receiving from nurses we interviewed. The form factor naturally progressed to something that was consistently well received by users.

Refinement

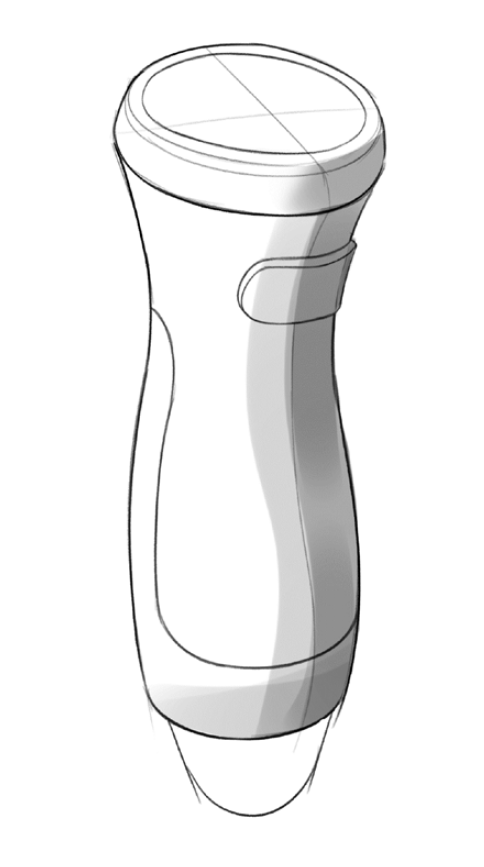

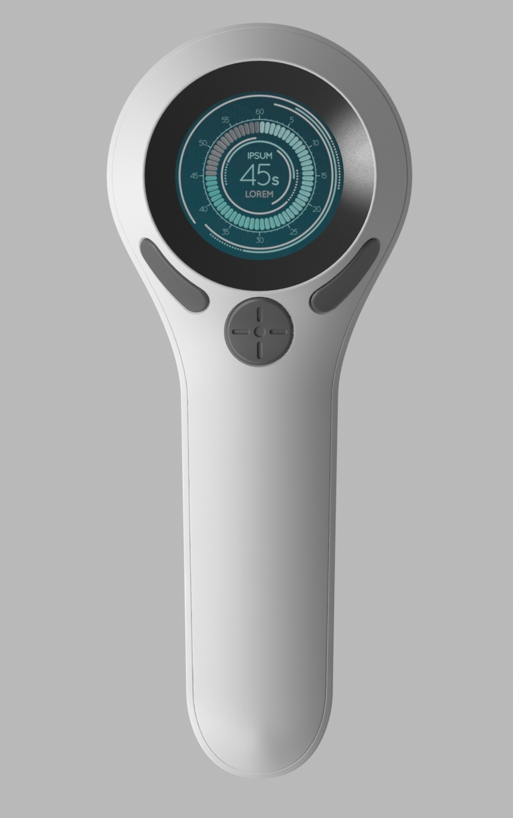

It became evident that users favored a vertical probe with a grip similar to that of a kitchen immersion blender. To explore this idea further, I created an inspiration board featuring various immersion blenders and used that to make a polished probe that more closely resembled a finished product.

I traveled with the marketing team to gather additional user feedback using this refined probe prototype. Visiting users at their workplaces and observing their workflow in person proved to be extremely valuable.

Data Analysis

Gathering data from users was only part of the overall task - this information had to be condensed and presented to the various stakeholders in the project, including marketing, engineering, and upper management. I utilized my data analytics and visualization skills to create figures and charts that effectively conveyed users' experiences with our prototypes. The visualizations would prove essential in making decisions throughout development.

Result

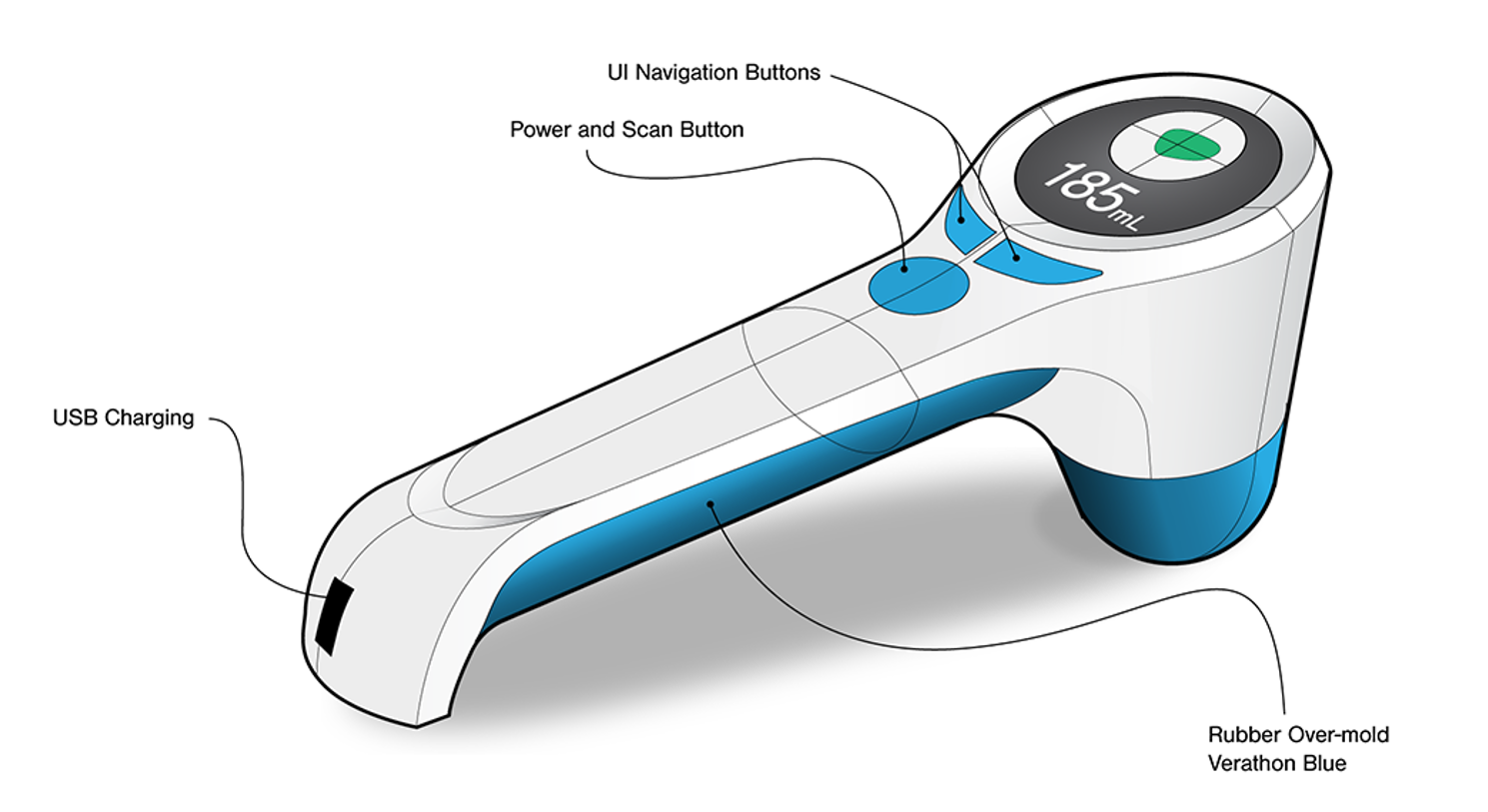

The final form factor was achieved after months of gathering user feedback. At this stage, I also had to consider the internal components and the manufacturability of the external housings. Some components required modification for injection molding, but the critical features developed from user feedback, such as the grip size and contours, were preserved. The result was a probe that was manufacturable, aesthetically pleasing, and, most importantly, highly praised by users.

-

Ergonomic, ambidextrous grip for ease of maneuvering during exam

-

Scan with ease by pressing a single, button which was optimized for comfort, haptic feedback, and response

-

2.1” round display is unobstructed during scan workflow

-

Easily cleanable to address infection control requirements

-

Unobtrusive orientation features for wireless charging dock